Thanks for your support! If you make a purchase using our links in this article, we may make a commission. And, as an Amazon Associate, I earn from qualifying purchases. See the full disclosure here.

Are you confused about which RV construction methods are best? Trying to distinguish between fiberglass finish or stick and tin exterior walls can be confusing. And should you get an aluminum frame and what about Azdel? Well in this article we discuss the best RV construction methods and which is best for you.

People buy travel trailers for many different reasons. That’s why there are so many choices on the market. A young couple may want an entry-level travel trailer under 3,000 pounds that can keep up with their outdoor activities. A large family may want a bunkhouse travel trailer with multiple LED TVs to appease the masses. An empty-nester couple may want a coach that has a pair of easy chairs next to a huge picture window, to enjoy the morning.

There are others that come armed with their RV inspection tool kits because they want to know what’s behind all of the glitz and glamour. They’ll ask questions like how are RVs framed? What is the best type of RV construction? Is fiberglass siding better than aluminum sheeting?

In this discussion, we’ll show you the difference between the conventional and laminated fiberglass RV construction methods. The example travel trailers we’re going to show you will point out the pros and cons of each method by section and topic of concern.

3 Different RV Building Methods

1. Conventional Travel Trailer Construction Method

The frame of the RV consists of 2 x 4 specially treated wood studs. Corrugated aluminum siding makes up the exterior sidewalls, and vinyl paneling makes up the interior wall surfaces. The floor uses wooden joists and trusses give the roof strength. The RV Industry refers to these travel trailers as “Stick and Tin” RVs.

2. Laminate Travel Trailers

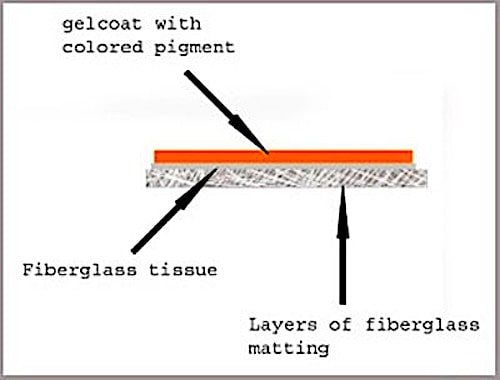

There are actually three RV construction methods for travel trailers. We just spoke about the wood-framed conventional versions. The second version has square aluminum tubing welded together for the frame. The exterior walls have flat fiberglass panels that are sealed with a thin lamination material to keep it weatherproof.

3. Molded Fiberglass Trailers

The third is the double-hulled molded fiberglass trailers where each half is dye-pressed into shape and sealed together. Examples of molded fiberglass trailers include RV companies like Casita, Escape, and Scamp.

When differentiating between the two, the RV Industry generally refers to the aluminum-framed version as “laminated” RVs while the dye-molded ones keep the name “fiberglass.” The molded fiberglass trailers aren’t relevant for this discussion since their subcategory is very different from the traditionally framed travel trailers.

Aluminum-framed travel trailers became popular as consumers looked for lighter RVs that have less impact on their fuel economy. The most recent surge of laminate trailers selling over conventional versions was in 2006-2007 when gas prices were climbing over $3/gallon before the 2008 Financial Crisis.

In today’s RV market, conventional travel trailers have adapted, making them more competitive with their laminated counterparts. Let’s take a look at a side-by-side comparison of two RVs that are nearly identical, but one has a wood frame and the other an aluminum.

RV Examples: Coleman Lantern and Coleman Light by Dutchmen

The Coleman Lantern Series by Dutchmen is one of the best travel trailers for newbies. This series has floorplans, features, and sizes that fit virtually every type of RV lifestyle for those just starting out. The quality is top-notch, that’s why Coleman licensed its brand to Dutchmen since 2010.

Our first example, the Coleman Lantern 285BH is a part of the Coleman Traditional lineup. The brand uses the word “traditional” in place of the conventional RV building method. The 285BH falls in the 6,000-8,500 lbs. level. The Lantern LT (3,600-6,000 lbs.) and Colemen (under 3,000 lbs.) sub-series offer couples and family-friendly versions that are easily towable by your fuel-efficient SUV or upcoming EV truck (sign up for your free copy of RV Camping Magazine to learn more about the all-electric trucks in the June 2021 edition).

The second example below is the Coleman Light 2835BH. You’ll find this one under the Coleman Laminate Series with weights above 4,500 lbs. If you’ve watched Colemen for a few years, you know that the small travel trailers were referred to as the Light LX. For 2022, they were given some excellent TLC and a name change to the Coleman Rubicon.

When you look at the Lantern 285BH and the Light 2835BH, besides the exterior skin, they look virtually identical. Each camping trailer has the same:

- Floorplan

- Ironwood fabric

- Maryland flooring

- Roman Maple cabinets

- Arabesque Crystal countertops

- Front pass-through exterior storage bay

- Walk-in pantry

- Front queen-size bed

- Full-size bunk beds

- Double-entry where the second door opens into the master bedroom

- The dinette and sofa on the single slideout on the off-door wall

- All-in-one bathroom with a large tub-style shower

- RV outdoor kitchen with the same features

We could list all of the similarities, but we’re sure you get the point. Here are the specs for each of the RVs. You’ll notice there are some differences. We’ll explain what these differences are and why they usually occur as we discuss the pros and cons of each RV building method.

| Conventional | Laminated | |

| Example Travel Trailer | Coleman Lantern 285BH | Coleman Light 2835BH |

| Length | 32.9 ft. | 32.11 ft. |

| Dry Weight | 6,611 lbs. | 6,574 lbs. |

| GVWR | 8,800 lbs. | 7,600 lbs. |

| CCC | 2,189 lbs. | 1,026 lbs. |

| Holding Tanks | F: 60 gal/ G: 42 gal/ B: 42 gal | F: 60 gal/ G: 78 gal/ B: 28 gal |

| Refrigerator | 7 cu. ft. | 7 cu. ft. |

| Decore | Dark brown cushions and cabinets with grey flooring and countertops | Dark brown cushions and cabinets with grey flooring and countertops |

| Sleep | 4-10 | 4-10 |

Benefit Comparison of RV Building Methods

The topics below don’t exist in a vacuum. While we’re pointing them out individually, you need to remember that they all work together. As you continue forward through this article, make sure you keep an open mind. You may find a few surprises about your preferred RV building method you haven’t considered before.

Exterior of Sidewalls

1. Aesthetics – TIE

At first sight, many prefer the smooth sidewalls of the laminated Coleman Light 2835BH. Having a flat canvas to add decorative decals makes the travel trailer look stylish and aerodynamic. Don’t discount what Coleman did with the 285BH. The grey trim below the white base and painted accents give the coach a great look. In the long run, the paint on the Lantern will keep its integrity for many more years compared to the decals on the Light.

2. Cleaning – Laminated

Two things you never want to use on any RV are a power washer and harsh cleaning chemicals. Read our article on How to Clean the Outside of a Camper Trailer for the best solutions to make your “Big Pretty” live up to its name.

The issue with cleaning Stick and Tin RVs is those little nooks and crannies the aluminum siding creates. After you clean most of it with a brush, you’ll still need to pull out the ladder and a rag to scrub those seams and corners. Those of you with shoulder or elbow problems need to be careful about aggravating your condition. You may want to call in your chips with the kids on this one.

3. Repairs- Conventional

Both exterior sidewall materials can take decades of punishment from the road, camping, and other conditions. In extreme situations, fiberglass and aluminum can crack open. Aluminum will bend before it breaks, still protecting everything inside. If the aluminum does break, replacing one of the panels is easier and less costly compared to the laminated RV.

Since the fiberglass panel is one piece, the whole panel and everything laminated on it needs to be ordered from the manufacturer and replaced. We discuss the details below, but the point is, that $5 crack turns into a $5,000 or more repair cost. You could use silicone caulk to seal it for a while, but if the crack gets bigger or a chunk of the fiberglass is missing, there might be a chance your extended warranty or RV insurance will cover it.

4. Weather Resistance- Laminate

When properly sealed, your travel trailer will be properly guarded against moisture seeping through. During hail or sleet storms, the dents in your aluminum siding will look like a morse code message from the New York and Mississippi Valley Telegraph Company in 1851 (we know them today as Western Union).

The fiberglass laminated panels fare well in hail and sleet. If it’s golf-ball-sized hail in high wind, RVs do have their limits. Both building methods use PVC, rubber, or other puncture-resistant materials on the roof to resist the punishment of weather, trees, and road conditions.

5. Towing Experience- Laminate

Laminated RVs are more fuel-efficient than stick and tin travel trailers. You can see some great examples in our RV Camping Magazine July Edition. It all has to do with wind resistance and the laws of aerodynamics. We’ll spare you the calculus, and give you the common language version.

As you drive, with a conventional sidewall travel trailer, the wind has to flow across all of the nooks, crannies, and corrugation. From an aerodynamic viewpoint, the surface space is doubled compared to a smooth-surfaced laminated RV. The effect on your miles-per-gallon can decrease by 1-2 miles.

Framing of Side Walls

1. Conduction- Conventional

RV manufacturers usually use pine for the wood framing. This isn’t the regular 2×4 you find at your local hardware store; it’s pressure treated with the Alkaline Copper Quaternary (ACQ) chemical. Structural plywood uses marine grade level sheets that are moisture and rot resistant due to the natural properties of the Douglas Fir or Western Larch within the material. This type of plywood isn’t pressure treated or given any additional treatment, except the glue that keeps the wood slats together. With RV preventive maintenance habits, marine grade plywood withstands the decay influencers like :

- Bacteria

- Fungus

- Mildew

- Moisture

- Mold

- Pests

- Rot

When it comes to temperature, wood is a natural insulator. It doesn’t conduct heat or cold like aluminum framing. This gives your coach’s climate-control or other RV heating systems a better chance to do their job without having to fight against the metal skeleton.

2. Corrosion- Laminate

On the other hand, the pressure treatment process removes all moisture from the wood studs and replaces it with the ACQ chemical. The marine-grade woods are naturally resistant to moisture and decay influences, but after 40-50 years, with proper preventive maintenance, the lumber will become vulnerable. If you want to recondition a wood-framed RV, speak to a local RV restoration expert near you.

Like your passenger vehicle, aluminum is strong enough to support RVs 45-feet long with all the trimmings due to its relative lightweight properties. Decay influencers can’t live on the metal, and aluminum resists rusting at the atomic level. You still want to make sure your seams are thoroughly sealed, but you can rest easy knowing your RV’s bones aren’t being attacked.

RVBlogger Tip about Rust: Please note that we said aluminum is rust resistant, not rust proof. If left to the elements without the proper care over a long period of time, aluminum will rust. We always recommend keeping your seams sealed, using an RV cover or tarp when storing your coach.

Cleaning your RV 3 times a year, makes the decay influencers disappear

3. Insulation- Conventional

If you judge an RV by its insulation R-value only, you’re only getting a partial look at the whole picture. The actual heat transfer resistance value of your travel trailer works on a number of factors. Are you parked in a shaded campsite? Do your windows have tinting or are they double-paned? Is your slideout, window, and door weatherstripping working optimally?

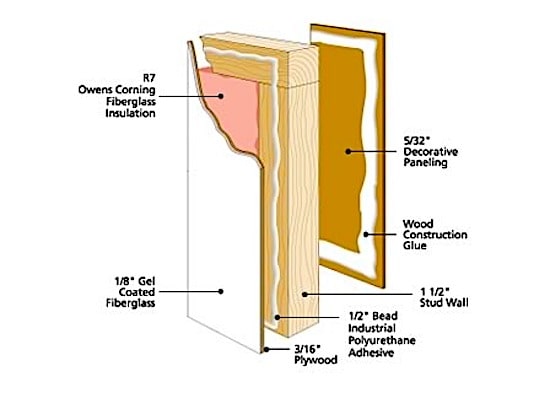

The differences in insulation are significant though. RV manufacturers, regardless of RV construction method, are placing fiberglass batt (the thick pink or yellow cotton-like insulation) in the subfloor and roof. Others are using rigid styrofoam insulation. So, it boils down to what’s going into the sidewalls, front cap, and rear cap.

Wood-framed travel trailers still use fiberglass batt insulation inside the walls. The average R-value of fiberglass batt is R-25. Aluminum-framed trailers have an average R-value of R-7. You’ll find Polyisocyanurate (polyiso), Extruded polystyrene (XPS), or Expanded polystyrene (EPS). DIY RVers and some manufacturers will use spray foam for the whole build or as a way to fill in the gaps.

4. Azdel- Laminated

Azdel is a lightweight building material found inside laminated RV sidewalls. It provides structural support, some sound reduction, and thermal insulating benefits. This building material is twice as strong as wood, but half the weight, making it a great substitute for lauan.

At first, Azdel was an engineering issue because it can’t hold screws or other fastening hardware. As a polypropylene and fiberglass compound, the product has a coarse surface that won’t hold paint or sand down to a smooth finished face. Like HDF fiberboard, Azdel is best used where it can’t be seen.

Interior: Features & Weight

| Conventional | Laminated | |

| Lantern 285BH | Light 2835BH | |

| Master Bed | RV queen | Residential Queen |

| Kitchen Sink | Single basin | Double basin |

| Awning | 20 feet | 16 feet |

| Refrigerator | Black insert on door | Stainless Steel door insert |

| Tanks | F: 60/ G: 42/ B: 42 | F: 60/ G: 78/ B: 28 |

| CCC | 2,189 lbs. | 1,026 lbs. |

1. Features- TIE

If you can, walk into the Coleman Lantern 285BH and then immediately check out the Light 2835BH. Pay particular attention to the differences in the features. The laminated Light 2835BH has the same features as the conventional Lantern 285BH, but there are slight changes.

For example, the refrigerator in the conventional RV comes with a black insert instead of matching stainless steel with the other appliances. The laminated trailer has a residential queen while the other has a short queen in the master bedroom. The 285BH has a longer awning that covers both entryways, while the fiberglass paneled RV uses a 16-foot version that exposes the front entry.

If you look at the holding tanks, you’ll see that the 2835BH gives you a bigger grey water tank, but smaller black water. Yet the Stick and Tin trailer keeps it simple with both sewer tanks measuring 42-gallons. These adjustments cater to different RV lifestyles and camp experiences.

2. Weight Effects- Conventional

| Conventional | Laminated | Difference | |

| Lantern 285BH | Light 2835BH | ||

| Dry Weight | 6,611 lbs. | 6,574 lbs. | 37 lbs. |

| GVWR | 8,800 lbs. | 7,600 lbs. | 1,200 lbs |

| CCC | 2,189 lbs. | 1,026 lbs. | 1,163 lbs. |

When you look at the basic weight differences between our example Coleman travel trailers, you’ll see significant differences. While the dry weight has a small difference of 37 lbs, the gross vehicle weight rating shows that the conventional trailer holds 1,200 pounds more.

Conventional trailers have higher cargo carrying capacities since they’re not made with lightweight substitute materials. That extra 37 pounds of dry weight comes from many things, but much of it is the sturdy wood framing that supports the weight of the RV and your cargo. If your RV lifestyle requires a lot of gear, a stick and tin travel trailer will give you the storage weight capacity you need.

How RV or Travel Trailer Construction Methods Affect Price

| Conventional | Laminated |

| Lantern 285BH | Light 2835BH |

| MSRP: $33,706 | MSRP: $36,264 |

1. Manufacturing- Conventional

The laminated RV building method first showed up in the latter half of The Classic Era (1971-1989). The Stick and Tin method we know today came together just before WWII in The Antique Era (1910-1944).

The extruded square aluminum tubing, specialized tools, and lamination process require training and certification to use correctly. All of this equipment and training have costs that get absorbed into the production cost of each unit produced. That’s why you’ll see a higher MSRP on laminated travel trailers when you compare them to their conventional sibling.

The conventional wood-frame building process usually relies on the commercial-grade version of the tools you have in your tool bay. The level of training required on conventional RVs while necessary can be taught to unskilled labor workers.

2. Repairs- Conventional

If something in the sidewall needs a repair, this is when the real difference shows up. In a conventional RV, an interior wall or access panel can be removed, and the component can be replaced.

If you watch the building process of an aluminum-framed RV, you’ll see that the sidewall is one piece. The framing, insulation, wiring, and other components get laminated to the fiberglass panel by heated pressure and a laminated coating. If one of those parts fails, the entire sidewall has to be replaced. Typically the cost and timeframe of the same exact repair are much higher than the Stick and Tin counterpart.

What is the Best Constructed Travel Trailer?

Only you can decide what the best constructed travel trailer is for you and your family. It boils down to what fits your RV lifestyle best. You’ll find that many of the big questions in the RV boil down to personal choice.

Is a Conventional Travel Trailer Worth It?

A wood-framed, corrugated aluminum shelled travel trailer gives owners strength advantages for additional gear and insulation for a longer camping season. Typically, Stick and Tins are better priced and easier to repair.

Weekenders that camp locally or full-timers that stay in one location for longer periods will benefit best from the purchase savings. Late season campers will enjoy the thicker fiberglass batt insulation. Boondockers can spend more time camping since the holding tanks are better suited for self-contained situations.

Is a Laminated Travel Trailer Worth the Money?

Aluminum-framed laminated fiberglass-paneled trailers are lighter, are more feature-focused, and have fuel-saving qualities while towing. Towables built with this RV construction method take less effort to clean and you don’t have to worry as much about the decay influencers weakening the support structure.

Part-timers or full-time RVers that travel often will want to focus their attention on this type of travel trailer. If you want a fuel-saving RV that’s SUV-friendly, this is the coach you want. Glampers will love the higher level of features but know that you’re going to pay more than a conventional travel trailer of equal size. The sidewalls are durable, but take a look at them once a month for any cracks, so you can seal them before they become a ghastly repair.

The Hybrid Construction Method – Forest River’s Grey Wolf Black Label

If you can’t decide between the conventional or laminated RV construction methods, why not choose both? The Cherokee Grey Wolf Black Label by Forest River gives you the wood framing and fiberglass batt insulation standard in Stick and Tin travel trailers. Yet, instead of the “tin,” it has the gel coated laminated fiberglass paneled sidewalls and back wall like a standard laminated RV.

The Cherokee brand continues to offer the Black Label option for the Grey Wolf Series on some of their popular models. When you compare the dry weight and GVWR, you’ll find that the Black Label Grey Wolf models sit in between the parent versions. Purchase pricing sits in that middle gap too.

When Cherokee builds the Black Label Grey Wolf, the framing and insulation are completed as if it’s a conventional trailer. They add a layer of lauan board (not Azdel) because this material works best making the transition between the fiberglass panels and the wood framing. Lauan has a long history in the RV World going back decades.

Haylett RV Does a Great Job Explaining RV Construction Methods

What is the Best Travel Trailer to Buy

When it comes to the conventional or laminated RV construction methods, the best travel trailer to buy is the one that satisfies your needs, wants, and minimizes those features you want to avoid. A great way to find this out is to try before you buy. Hop on to a peer-to-peer RV rental company website like Outdoorsy, RVshare, or RVezy and make a few reservations to try out some different models. You’ll find that firsthand experience combined with your online research work well together.

Related Reading:

1. Gas vs Diesel RVs – Which are Best in Terms of Fuel, Maintenance, Longevity and Insurance?

2. RV and Travel Trailer Insulation R-Values Explained

3. Ultimate Guide to Understanding RV Model Numbers and Letters

4. 7 Best Fiberglass Travel Trailer Brands

Don’t forget to hitch up to all of our sources to get the full RVBlogger experience. Our website has hundreds of blog articles on topics you want to learn about. Whether you’re just starting to search for your first RV, want some advice on how to enhance your RV experience, or need some recommendations on essential accessories, you’ll get the most accurate information. You can also find us on Instagram.

If you’re looking for RVs with particular features, need a walk through on popular apps or processes, or are searching for some exclusive RV discount codes to the best resources, subscribe to the RVBlogger YouTube channel where we publish new content every Sunday.

Join in on the discussion on our Facebook Page, RV Camping for Newbies. We have thousands of RVers across the country helping each other out with their peer-to-peer suggestions and advice. You’ll find people from all walks of life who travel in every category of RV, with RV experience across the board.

If you want to learn about great destinations, RV repair tips, industry trends, RV influencers, and much more, sign up for your free copy of RV Camping Magazine. Our monthly digital magazine is written by many known experts in the RV World including the National RV Training Academy. We also include our weekly e-newsletter that highlights news this week in the RVBlogger Universe.

As always, from Mike and Susan, thanks for reading, and we’ll see you next time!